Heavy duty paper cutters may be fairly simple machines in their design but choosing the best industrial paper cutter for your needs, and one that will last for years, is not always simple.

You’ve decided to buy a new industrial paper cutter and have done all your homework, reviewed proposals, read literature and even learned terminology. But if you’re like most, you’re still a bit confused about features, various options (how do you decide?) and the extensive terminology.

We guide every customer through the process of choosing a paper cutter that will meet their needs and will last for years to come, even if they don’t end up buying one from us. We’ve been the Cutter People for over 85 years, it’s in our blood.

Finding The Best Commercial Paper Cutter: Buying Basics

Guillotine paper cutters can be found in nearly every print shop. While safety and performance have improved in recent years, paper cutters still contain the same basic components— a knife, clamp, table and backgauge—that they’ve had for the past century. As a result, industrial paper cutters normally have a long usable life.

Unlike other equipment, such as pre-press, that have seen radical changes in technology, the most important factors to consider when purchasing a paper cutter are not the brand or computer system. It is more important to consider the following:

- What size material will you be cutting?

- Which types of material will you be cutting?

- How much time will be spent cutting?

- Is the machine supported with service and spare parts?

- Does it meet current safety standards?

Ignoring these basic considerations can make any paper cutter the wrong cutter for your needs.

No matter what you end up cutting with, we've put together some helpful guides to getting the job done right every time. See our Commercial Paper Cutting Troubleshooting Guide and Caring for Industrial Paper Cutter Knives.

1. Size of material to be cut

Size of the material being cut is an important factor when choosing a paper cutter. ALL paper cutters have a fixed cutting width. If your material fits in the machine, it can be cut.

However, there are other factors to be considered:

- Is there enough room to properly align the material against the side guides?

- Is there enough room to reposition and turn the material if necessary?

Sheets have two dimensions, length and width. If the cutter is larger then those dimensions, the material to be cut will fit. But an additional consideration, one that is often missed, is what happens to the material during the cutting process.

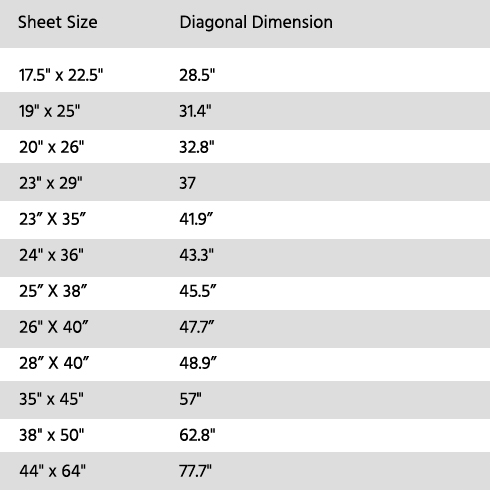

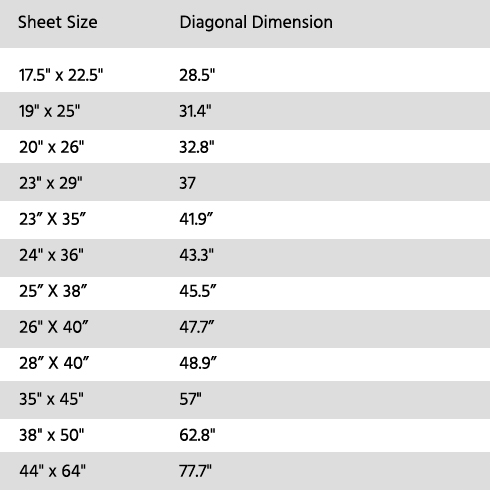

For print shops looking to split larger sheets, a cutter that will handle the short size and allow for splitting of the longer size may be acceptable. However, when sheets need to be trimmed on all four sides, the cutter size must be larger than the longest dimension to allow for turning and alignment on the cutter table. The longest dimension on a sheet is measured on a diagonal corner to corner. The calculation for determining the diagonal of a sheet is A2 + B2 = C2.

The following table lists the diagonal dimensions of common paper sizes:

Determining if there is enough room to reposition material

While the table above gives the diagonal dimensions of full sheets, the fact that they will be trimmed needs to also be considered.

For example, if we look at the common sheet size of 25 x 38", we find the diagonal to be 45.75". This is larger then today's popular 45.25” cutter size. However, if we trim ½" off the 38" dimension, the diagonal drops to 45.07". The lift can then be turned on the cutting table.

2.Type of material to be cut

The second critical factor to consider when purchasing a paper cutter is what type of material you will be cutting. If you are only cutting paper, this is not a large concern.

But if you are cutting more difficult material, a stronger machine may be required. This is especially true if you need to cut laminated board, plastics, printing plates and composite materials. While using special blade angles may help improve cut quality, nothing will replace the need for a heavy-duty cutting machine with the strength to handle cutting these hard materials. In many applications today, especially in the recycling industry where a variety of materials are cut simultaneously, an older mechanical machine may be the best alternative.

3.Quantity of material to be cut

The final important consideration is the amount of time that will be spent operating the paper cutter: Will it be running three shifts per day, seven days a week or will it be used only a few hours per day?

Many paper cutting machines are built to run around the clock, so if you only need to run yours for a few hours a day, you will likely end up buying more machine than you need. While everyone likes a new machine, your work may not justify the additional expense. That’s where reconditioned paper cutters come in.

Buying a reconditioned paper cutter could save you 30-50% off the cost of a new paper cutting machine. In other situations, it may be more practical to consider purchasing a certified used paper cutter. While you may lose some of the features found in a new machine, they are not necessary in a cutter that is being used only part-time. For example, while a computer controlled back gauge can save an operator hours of cutting time, that savings dwindles on a machine being run only a few hours per week.

See our Reconditioned Paper Cutter Buying Guide: What You Should Know.

It is possible to find new paper cutters that are both long-lasting and economical, though they are somewhat rare. Take a look at Colter & Peterson’s Saber® paper cutter, which ranges in size from 37” – 141”, and its Prism® paper cutter which comes in sizes as small as 31.5”.

There are more paper cutter options available today than ever before—over a half dozen new machines and a wide range of used machines to choose from. One thing remains the same: Consider first which cutting machine is right for your job needs and how you’ll use it, regardless of brand, options, machine age or allegiance to a vendor.

4. Service and Support

Many manufacturers of commercial paper cutters have closed, and parts as well as service may be difficult to obtain. Other manufacturers limit the machines they will support to machines newer than 20 – 25 years old, making service and parts difficult to obtain. Colter & Peterson supports many of these models, even if the original manufacturer can’t do so.

Request a free service & support assessment. Let us know which machine you’re considering, and we’ll let you know its service and support status.

5. Safety

Safety standards have changed dramatically over the past half century. All paper cutters being sold or re-sold today should meet the manufacturers recommendations and/or current ANSI safety standards. Colter & Peterson sits on the ANSI Board for guillotine safety (B-65.3) and thoroughly understands these standards.

If you are purchasing a paper cutter or paper handling system, we can help you determine whether it meets current safety standards. Request a free paper cutter safety assessment.

Ready to for more tips on selecting the right paper cutter? Let’s dig in, in the final segment of this series: Finding The Best Industrial Paper Cutter: What You Need to Know, Part 2.

Related Articles:

Finding The Best Industrial Paper Cutter: What You Need to Know, Part 2

Reconditioned Paper Cutter Buying Guide: What You Should Know

Caring for Industrial Paper Cutter Blades: Quality Cuts, Greater Savings

Commercial Paper Cutting Troubleshooting Guide: Problems and Solutions