The best results in paper cutting (as in anything else) begins with selection of the right equipment. This is especially true with the guillotine knife in a industrial paper cutting machine. An inferior quality paper cutter blade inaccurately ground with an incorrect bevel may not only result in a poor quality product being produced, but could increase costs and even damage a commercial paper cutter.

How to select a paper cutter blade

Selection of a paper cutter blade is critical. Always buy from a reputable manufacturer or supplier, one who is aware of the latest developments in paper cutter blade sharpening and has enough experience to provide your shop with support.

Blades for guillotine paper cutters are available in three major types. (While some manufactures have developed other variations of paper knives, they are beyond the scope of this article).

- Standard steel knives

- High-speed steel knives

- Carbide knives

The difference in paper cutting knives is in the type of steel used in the inlays. While standard steel knives have been and will continue to be an acceptable type of knife, the popularity of high-speed steel knives have grown due to their improved performance, both in the quality of cut and increased life between grindings.

High-speed knives cost about twice as much as standard knives, but as they can last 2-3 times longer between sharpening. The additional cost can easily be offset by the reduction in knife change time and knife sharpening costs.

Carbide knives provide the best quality edge and last even longer than high speed steel knives, but they are the most expensive (often 3-4 times the cost of high-speed knives) and require special grinding equipment to sharpen (also 3-4 times the cost of sharpening high-speed knives).

They are also very susceptible to chipping and due to their high cost, are only recommended for operations that are consistently cutting the same type of material such as fine paper, where the chances of damage from material is minimal. Carbide knives should NEVER be used when cutting any type of recycled material.

Paper blade bevel, length and angle

Knife manufacturers vary only slightly in their recommendations for a standard bevel (24° to 25°). There are times when a different bevel or even a double bevel is advisable, depending on the material to be cut.

The following chart illustrates some of the different bevels and will serve as a guide for obtaining the correct bevel for a particular material. Knife suppliers and machine manufactures all have information available to assist in determining the correct bevel to use with hard-to–cut materials.

Figure 1: Paper blade bevel guide, by material to be cut

| Material to be cut |

Paper Knife |

a |

b |

h (mm) |

Pressure |

false clamp plate |

| Bible paper |

HSS, HM, UFK* |

24° |

|

|

1500-2000 |

false clamp plate |

| Double waxed papers |

HSS, HM, UFK |

24° |

|

|

3200 |

** |

| Printing papers, regular |

HSS, HM, UFK |

24° |

|

|

2500 |

false clamp plate |

| Duplex papers |

HSS, UFK |

24° |

26° |

2,0 |

3000-3500 |

** |

| Flimsy |

HSS, HM, UFK |

19° |

|

|

3000-4000 |

false clamp plate |

| Label papers |

HSS, HM, UFK |

24° |

|

|

3500-4000 |

** |

| Felt-cardboard |

HSS, HM, UFK |

24° |

|

|

2000-2500 |

false clamp plate |

| Photographic papers |

HSS, HM, UFK |

24° |

|

|

2500-3000 |

** |

| Gummed papers |

HSS, HM, UFK |

24° |

|

|

2500-3500 |

** |

| Carbonizing papers |

HSS, HM, UFK |

19° |

|

|

400 |

false clamp plate |

| Carbon papers |

HSS, HM, UFK |

22° |

|

|

800-1000 |

** |

| Art papers |

HSS, HM, UFK |

23° |

25° |

3,5 |

3000-4000 |

** |

| Plastic fiber paper |

HSS, UFK |

26° |

|

|

2500-3000 |

|

| Blotting paper |

HSS, HM, UFK |

19° |

|

|

2000-2500 |

** |

| Metallic papers |

HSS, HM, UFK |

24° |

|

|

3000-3500 |

** |

| Parchment paper |

HSS |

24° |

|

|

2500-3000 |

** |

| Glassine paper |

HSS |

24° |

26° |

3,0 |

4000-4500 |

|

| Stencil duplicator paper |

HSS, HM, UFK |

19° |

|

|

3000 |

false clamp plate |

| Writing papers |

HSS, HM, UFK |

24° |

|

|

2500-3000 |

|

| Tissue paper |

HSS, HM, UFK |

19° |

|

|

2000 |

false clamp plate |

| Autocopying paper |

HSS, HM, UFK |

24° |

|

|

800-1000 |

** |

| Transparent papers |

HSS, HM, UFK |

24° |

|

|

3000-3800 |

** |

| Velours papers |

HSS, HM, UFK |

19° |

|

|

2500 |

** |

* HSS = high-speed steel knives

HM = carbide-tipped knives (normal: 23/25°)

UFK = ultra-finest grain hard metal (normal 22/25°) |

** Compensation of differences in height is necessary |

Source: Polar-Mohr® "Cutting in Practice"

Download Polar Mohr's knife bevel guide showing in detail the recommended knife angle for every type of material to be cut, from paper and cardboard to plastics and packing materials.

Keep the paper blade sharp to save money and time

After selecting a good quality knife, it is equally important that the knife be kept sharp at all times. A dull paper knife is an unnecessary waste, especially in a competitive market. It must push its way through the cutting material and when dull, requires up to three to four times more force than a sharp paper knife. A dull knife increases energy usage, wears the paper cutter prematurely and drives up other production costs due to inferior work.

A lift cut with a dull knife has a rough, burry, at times "sealed" edge. This can be quite expensive, as it creates separating problems in subsequent operations like feeding on a folder.

When to change paper knives: know the signs

How do you know when your paper cutter knife needs sharpening? It’s the responsibility of the paper cutter operator to know when a paper knife change is necessary—so he or she must be able to recognize the signs of a dull knife.

A general reference is to change the blade:

- every 2,000 cuts using a standard knife

- every 4,000 cuts using a high-speed knife, and

- every 12,000 cuts using a carbide knife.

Despite these guidelines. it may be necessary to change the blade if the knife appears dull.

Signs of a dull paper cutter knife include:

- Diminished cut quality and appearance of material surface

- Change in the sound of the knife going through the pile

- A burnish on the face of the cut material

Any of these signs should indicate to the experienced paper cutter operator that a knife change is in order. Cutting coated stock, board or plastic material will dull a blade more rapidly than cutting standard uncoated stock and other fine paper. The more abrasive the nature of the material being cut, the faster a knife change becomes necessary.

Some job problems are related to inaccuracies in loading the paper or settings on the paper cutting machine. See our Commercial Paper Cutting Troubleshooting Guide.

How to lengthen the life of your paper cutter blade

Frequent knife grinding will materially lengthen the life of the knife, saving you money in the long run.

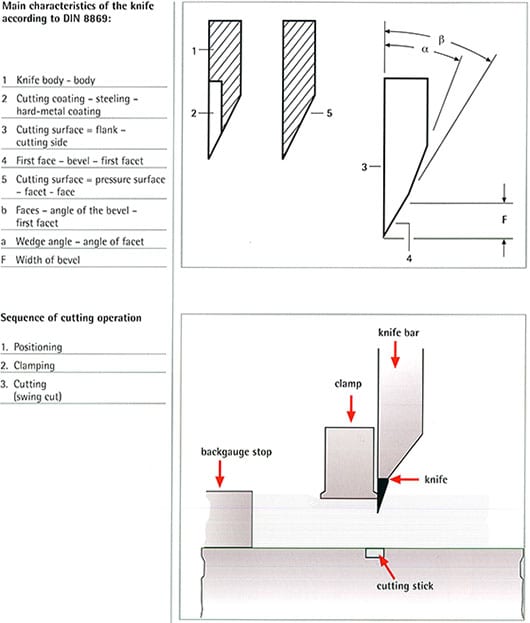

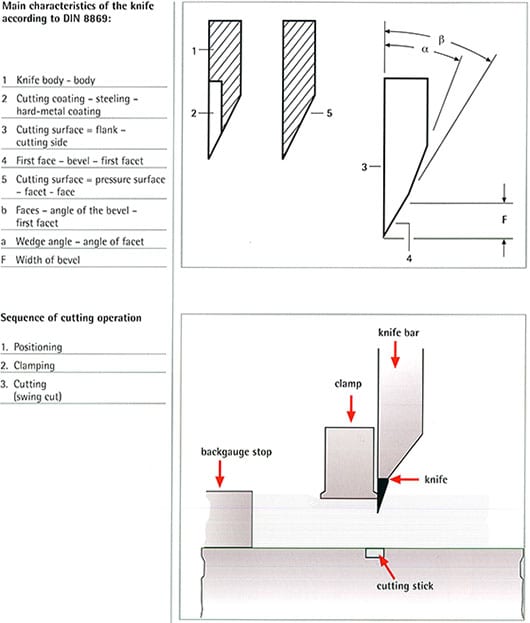

The magnified cross section of a paper blade in Figure 2 shows that only about 1/32" of the metal is removed in order to re-establish a keen cutting edge—as long as it’s done when sharpening first becomes dull.

Figure 2: Diagram of paper blade sections

Source: Polar-Mohr® "Cutting in Practice"

If the paper knife is permitted to become extremely dull, which occurs at an accelerated rate once the sharp edge is worn off, a great deal more (up to ¼") must often be removed to restore a keen edge.

If the paper knife becomes very dull, you can be charged for the additional time required to restore its edge. If you permit the paper cutter knife to become extremely dull, only a few sharpenings can be made before the knife becomes too short for further use. You are literally grinding your knife investment away.

The cost of changing knives can be seen in this light too:

Let’s assume a 45" paper cutter costs about $120.00 per hour to operate. It takes approximately 10 minutes to make a complete knife change cycle, so a knife change in this scenario would cost about $20.00. A 26" x 40" folder has an hourly cost of about the same as a paper cutter. Misfeeding the folder (resulting from "sealed" or burred edges caused by a dull knife) could cost more than a knife change.

Just one bad feeder jam-up, resulting from misfeeding or feeding doubles, could certainly take more time to clear up than the cost of a knife change and a number of small jam-ups will, of course, have the same result. If you are cutting paper to feed a press, this situation becomes even more costly.

Any way you figure, it pays to keep a sharp blade in your paper cutter.

How to change industrial paper cutter blades

The procedure for changing knives will vary depending on the make and model of the cutting machine. But no matter the cutter, the majority of operator accidents happen during the knife-changing operation. It’s extremely important that each operator develops good safety habits, follows the manufacture's procedures and be provided with a safe machine.

The knife on a 45" paper cutter weighs about forty pounds. If it slips and catches a hand or a finger between it and the table, no imagination is needed to figure out what will happen.

Modern paper cutters have safety devices built into them to reduce this danger. Even so, carelessness will negate even the best safety devices.

Following these blade sharpening safety recommendations should reduce the risk of accidents, regardless of the age and make of the paper cutting machine:

- Place an empty knifeboard on the cutter table before removing the dull knife from the machine. The knife can then be secured to the board immediately upon its removal.

- Always use the proper knife handles, making sure they are properly installed.

- Never allow the sharp edge of the knife to be unnecessarily exposed in a manner that could lead to it being accidentally contacted or bumped.

- Know and follow the manufacture's procedures when changing knives.

Remember, keep handling of the unprotected knife to a minimum. By insisting that your operators follow the correct procedures in caring for your paper cutter blades, you will minimize danger to the operator, save time and money and increase the quality of your work.

See our guide to Commercial Paper Cutter Safety: Standards and Accident Prevention for more safety tips.

Want help? Get in touch with a paper cutter expert

No matter your level of experience with paper knives, reaching out to a pro can help. Contact us with any of your knife grinding or handling questions and we’ll get you in touch with the experts at Tri-State Knife Grinding. They’ve spent 65 years perfecting paper knife sharpening and use state-of-the-art sharpening and honing machines operated by only the most experienced knife grinders. It’s how they deliver the highest quality precision grinding and professional services every time.

Ask about sharpening services or purchasing paper knives, slitters, sheeter blades, trimmers, cutting sticks, saw blades and paper drills.

Related Articles:

Commercial Paper Cutting Troubleshooting: Problems and Solutions

Paper Cutter Safety: Standards and Accident Prevention

Finding The Best Industrial Paper Cutter: What You Need to Know, Part 1