Cutting paper, while a simple operation, is one that can present serious hazards to operators. Safety standards and regulations exist in various forms around the world as a result. The increase in “international” machines has seen these different standards slowly begin to merge. It has also led to some confusion, which we’ll unravel here.

U.S. safety standards

In the United States, safety regulations are part of OSHA law. While far reaching, the OSHA law concerning paper cutters is not very well defined, and leaves a lot to interpretation. OSHA specifically mentions guillotine paper cutters in two small paragraphs, stating these machines need some form of two-hand start and hold control for engaging a cycle and some form of a non-repeat device.

However, due to the fact that industrial paper cutters are classified as hazardous machines and are somewhat similar to metal stamping machines, inspectors can apply a variety of different standards when inspecting a paper cutter. The other forms of safety standards that exist in the United States are the National Safety Council (NSC) and American National Standards Institute (ANSI) guidelines. These sets of standards, while much more defined and specifically written for commercial paper cutters, are only guidelines and not law.

European (CE) safety standards

In Europe, the variation in safety standards was eliminated in 1995. New legislation was enacted to standardize the safety aspects of all new paper cutters sold into the European market. As a result heavy duty paper cutters have to be built to the "CE" standards for guillotine paper cutters sold in Europe.

Many other countries are in the process of adopting parts of these regulations into their own. For example, in the United States, the CE standards were incorporated into the ANSI B-65.3 standards for guillotine paper cutters.

Paper cutter clamps: The first thing to come down

Clamps have been responsible for the majority of accidents on industrial paper cutters and it’s easy to see why. Operators have been used to working in close proximity to the clamp when lowering it by using a foot pedal so as to see where the cut will be placed. They sometimes get their fingers caught in this process.

The main change coming out of new safety standards reduced both the pressure and the speed of the clamp when using the foot pedal. An effective cut line clamp system that shows where the knife is going to cut, without lowering the clamp, reduces the need for using the foot pedal and can also save time. A useful aid to save operators from placing their fingers under the clamp are push-outs (or “ream ejects”) in backguage programs that push paper forward and into the operator’s hands automatically.

The main cut: two hand operation and no tie-down

The action of cutting is always a safety concern. Years ago, an operator would pull on levers or pressed buttons when he or she considered it okay for the cut to take place.

Modern safety regulations are concerned with these two important goals:

- The cut only take place when intended

- If someone gets in the way, the knife or clamp will not cause harm

Current regulations, and this is one point that OSHA is very clear about, require a two hand start and hold system with anti tie down circuit be used. Essentially, both hands must be used together, within a half of a second, to initiate the cut. Both hands must remain on the buttons or switches until the knife has completed its downward travel.

Anti tie-down (or no tie-down) means that in addition to both hands being used to initiate each cycle, the switch must be released after each cycle. The system cannot allow one switch to be held or tied down while the machine is operated.

See our Caring for Industrial Paper Cutter Knives guide for safety tips during knife changes.

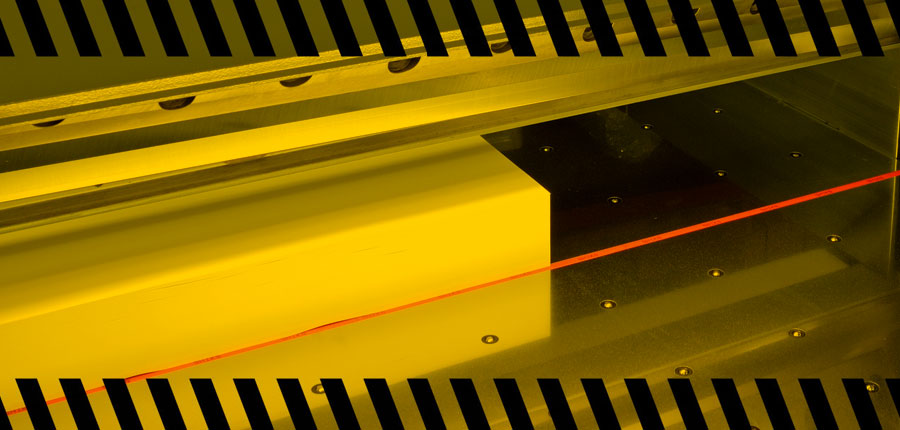

See the light: infrared eye beams

Operators aren’t the only people involved in the cutting process so safety standards must address assistants (who might be removing finished paper from the table) possibly entering the danger zone.

Modern requirements require a light guard (Electro Sensitive Protective Device) to be fitted on the front of the heavy duty paper cutter to an exacting specification. On modern light guards, visible light is no longer used; infrared beams are now the norm. This technology has the advantage of being encoded, so the paper cutter’s guarding system will not see any other infrared light source.

Many early types of light guards were used on larger cutters and generally operators took the view that such guards were 100 percent reliable. This unfortunately was not always the case, and some accidents resulted.

Two main problems with light guards were found:

- The guard may not have been positioned to ‘see’ the operator’s limb

- The guard simply did not prevent the cut/clamp action even when it did see an obstruction.

Modern regulations addressed the first problem by determining a minimum distance for light guard beams to be located from each other, thus detecting a finger rather than a wrist. The minimum distance from the beams to the knife and also to the surface of the table has been fixed as well.

These factors are variable depending on the “total stopping time” of the machine. (The total stopping time is the length of time it takes for the guard to detect an obstruction the electronics and relays in the cutter to respond and the clutch/brake or hydraulics to stop the knife).

The longer the total stopping time, the larger and further away from the cutting stick the light guards will be.

Backing up: preparing for parts failure

Today’s safety standards require the electrical system of a paper cutter to have enough backup, (redundancy) to ensure that safety will be maintained even if some critical part fails at the wrong time.

Much work has been done to improve reliability. In the past when one relay may have been used, if it failed the knife would not stop. Now at least two relays must be used. If either relay fails, automatic testing will reveal a fault and lock the machine out. The other relay will still prevent an accident.

Safety standards also require that a safety bolt or latch must be fitted to back up the clutch/brake (or hydraulic ram), thereby preventing the knife from making an unintended cycle.

Covering up: preventing “reach in” accidents

Today’s regulations require that most moving things be covered, making industrial paper cutters finger proof (prevent “reach in” accidents). The rear of the table has covers to prevent a hand being trapped between the clamp and the table surface or backgauge.

The opening in the center of the table for driving the backgauge will have a slot closing tape to cover trapping points at each end. Fixed covers may be fitted to prevent the operator’s fingers from being caught in the openings between grids on the rear of the clamp and backgauge (the light guard or backgauge speed may also be used to prevent this).

The front face of the clamp should have a smooth surface with all holes covered and be located a minimal distance from the rear face of the knife to prevent pinch points. The front of the table should extend far enough forward of the knife to prevent accidents. In addition to the light guard, side tables are also required to achieve this.

The end result

Tremendous strides have been taken to improve the safety of guillotine paper cutters. As a manufacturer, distributor and rebuilder of commercial paper cutters, Colter & Peterson is constantly aware of both current and proposed safety requirements. We have worked with a number of manufactures to ensure their products comply and are involved as a member of the group creating new ANSI standards.

We have also developed a number of updates that will allow some older cutting machines to comply with the current or proposed ANSI standards. Although some machines can be retrofitted with many of the updates mentioned, it is not possible on all models. In many instances it is more economical to trade in older machines for newer models.

Ask a paper cutter expert whether your old paper cutter can be updated to modern safety standards or inquire about trading in an old paper cutting machine. Whether you purchased your cutter with Colter & Peterson or not, we’re happy to help. We’ve been the Paper Cutter People for nearly 100 years – it’s in our blood.

Related articles:

Commercial Paper Cutting Troubleshooting Guide: Problems and Solutions

Caring for Industrial Paper Cutter Blades: Quality Cuts, Greater Savings

Finding The Best Industrial Paper Cutter: What You Need to Know, Part 1